Freeze Drying of Diagnostics and Reagents: An Essential Industry Tool

Diagnostic products are notoriously sensitive to light, oxygen, and temperature, making freeze drying an elemental industry tool to reduce the risks of long-term storage. Through features such as freeze drying at consistent low temperatures, backfilling product vials with inert dry gas before sealing, opaque freeze dryer doors, and low-light processing environments, these products become stabilized for dramatically longer shelf life.

Freeze drying eliminates the need for storing and transporting frozen material. With freeze dried diagnostic materials, you get quick rates of reconstitution and preparation of products to employ right away or store ready-to-use.

Diagnostics Innovations Rely On Freeze Drying

The diagnostics field in both human and veterinary medicine is changing, especially with developments in chip-based products. Freeze dryers can process diagnostic materials from the basic reagents to “labs-on-a-chip”. Quite often the diagnostic kit container produces challenges for the freeze drying process. Our knowledge of heat transfer and experience solving these unique problems enables us to configure the proper freeze dryer to reduce your freeze drying cycle times.

Freeze drying is also crucial when it comes to PCR (polymerase chain reaction) diagnostic procedures, which usually involve multiple reagents mixed together. A combination of reagents must be replicable with precision for each sample, in order to avoid errors and inaccurate results. When the reagents are freeze dried, they’re stabilized for a reproducible process and protected for storage and extended shelf life.

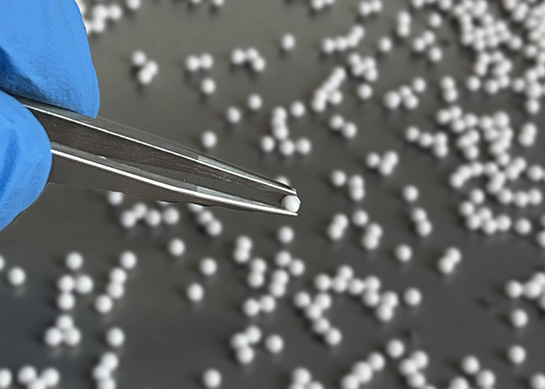

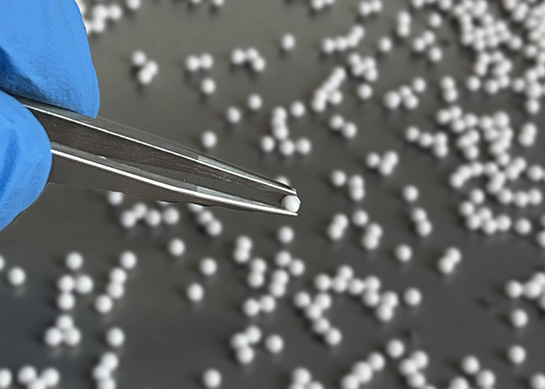

Millrock Technology also offers turn-key solutions for LyoBead production that include a bead dispenser (BeadLab), sealable tray, and freeze dryer. The combination provides all the necessary parts to quickly implement using LyoBeads, resulting in a final product that is a consistent volume stable dry bead ready for long term storage that is easily reconstituted.

Customized Solutions for Diagnostics Freeze Drying Applications

Millrock’s team understands that your needs for freeze drying diagnostics and reagents may be specialized. Our engineering staff designs our technology with your application challenges in mind, developing products that are more robust and reliable. Every component of our products are engineered with a purpose. From the design of our refrigeration systems to the proper use of instrumentation, all product components are high-quality and right for processing your valuable freeze-dried products.

Our REVO® Research and Development Freeze Dryer, Magnum® Pilot Freeze Dryers, and EPIC Small Production Freeze Dryer are specifically designed to process well plates and other materials for the diagnostics industry. These systems offer robust refrigeration systems for long term reliability, as well as sophisticated control systems with robust data collection and reporting.