QuantaS™ Steam Sterilizable

Production Freeze Dryer

Pharmaceutical Freeze Drying in a Sterile Environment

The QuantaS Steam Sterilizable Production Freeze Dryer supplies cGMP pharmaceutical freeze dryers with steam sterilization (SIP) and 21CFR part 11 for demanding applications in bio-pharmaceutical and pharmaceutical applications.

Choosing the right freeze dryer is often pivotal to the production of a great product and to long term company success. At Millrock Technology, our collaborative approach to system selection, customization and design provides the best freeze dryer for your production needs. Our support lasts throughout the production freeze dryer life cycle to help ensure that your project starts successfully and remains successful.

Our Steam Sterilizable Production Freeze Dryers include:

- All wetted components 316L stainless steel

- Sterilization (SIP) temperature: Controllable 121-125 degrees C

- Evacuation and drying: Water ring pump

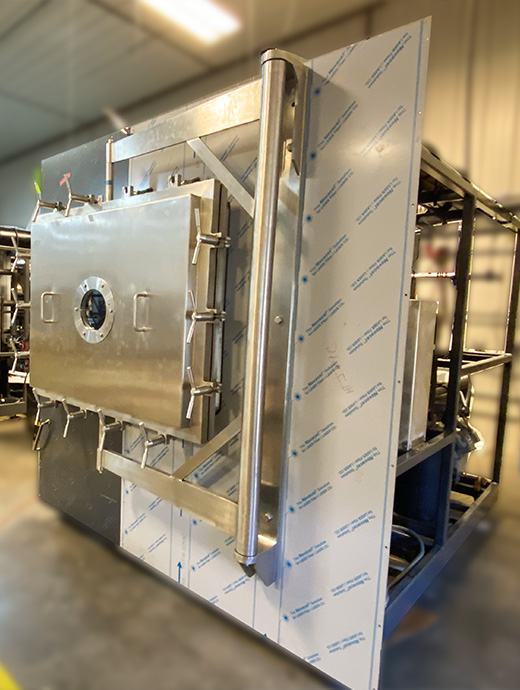

- Insulation: High temperature CFC-Free foam with a stainless steel shroud around both chambers

- Filter: 0.2 micron Sartorius with integrity testing ports

- System cooling to ambient and drying in less than 2 hours using the refrigeration system and a liquid ring pump

- Slope to drain

- Customized for your application needs

About the QuantaS Steam Sterilizable Production Freeze Dryer

QUANTA-S STANDARD FEATURES |

|

|---|---|

| Control System | Opto 22 or Allen-Bradley®️ |

| Shelf Temperature Range | -60C to +65C (+80C option) |

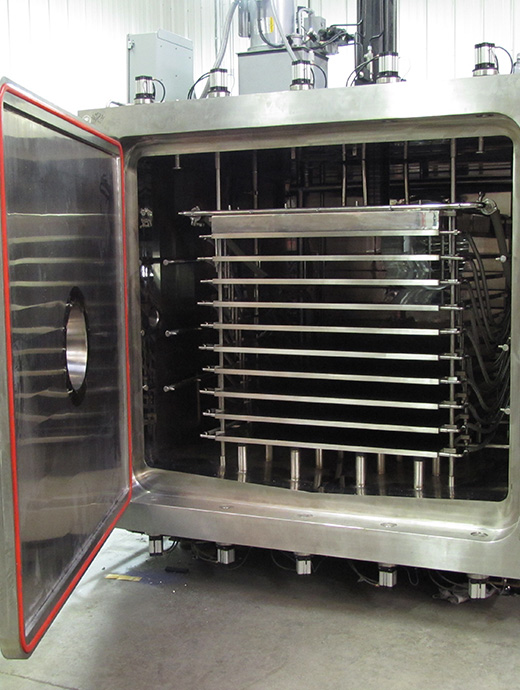

| Shelf Heat Transfer | Hollow, Fluid Filled |

| Shelf Material and Finish | 316L stainless steel, 20 Ra or better. Optional electropolish |

| Shelf Area | Up to 250 sq ft (23.226 sqM) |

| Shelf Stack | Bulk or Hydraulic Stoppering |

| Product Probes | 1 “T” type thermocouple/shelf |

| Condenser Temperature | -75C dry and empty |

| Chamber Configuration | Cylindrical or Rectangular |

| Chamber Rating | ASME 25psi at 125C |

| Condenser Style | Exposed Coil, Internal/External |

| Compressors | Two Stage, Carlyle, Bitzer, Mycom (screw) |

| Defrost | Steam |

| Vacuum Pump | Two Stage Oil Sealed Rotary Vane, Dry (optional) |

| Vacuum Control | Capacitance Manometer, Proportional Vacuum Control (optional) |

| Water Ring Pump | Included standard |

| Frame | Welded and Painted |

Note: Performance specifications are estimates and may change based upon design. Specifications subject to change without notice. All specifications based on 20C ambient on 60Hz.

Millrock Technology, Inc offers 21 CRF Part 11 control system that provides the necessary platform to meet the needs of cGMP freeze drying manufacturing. All data is stored in a secure SQL database to prevent manipulation. Program access is controlled through a multi-level password system to limit access to critical areas. New and modified data entry requires electronic signature that is level controlled to prevent unauthorized changes. All changes are logged in a change log database to provide a full audit trail that meets FDA requirements.

VIAL CAPACITY

| LYOPHILIZER VIAL CAPACITY by Shelf Area (sq ft) | ||||||||

|---|---|---|---|---|---|---|---|---|

| VIAL (ml) | 8 | 12 | 30 | 50 | 60 | 96 | 144 | 250 |

| 2 ml (15mm) | 3496 | 5080 | 13190 | 21424 | 26780 | 43888 | 66500 | 109166 |

| 5 ml (22mm) | 1612 | 2380 | 6100 | 10050 | 12560 | 20120 | 30900 | 50375 |

| 10 ml (24mm) | 1288 | 1835 | 4940 | 8170 | 10220 | 17032 | 25500 | 40250 |

| 20 ml (29mm) | 872 | 1290 | 3320 | 5610 | 7020 | 11344 | 17400 | 27250 |

* Number of vials is an approximation. Actuals can be provided as required.

Not sure which freeze dryer best fits your needs? Click here for our freeze dryer capacity calculator.

- Cooling Jacket on Chamber and Door

- Clean-In-Place Piping and Control*

- Pass-through Design

- Single Height Loading with Pizza Door

- Auto Load/Unload Options

- Internal Condenser or External Condenser

- Isolation Valve

- Bulk or Hydraulic Stoppering

- Bellows Seal on Hydraulic Stoppering

- Acrylic or Stainless Steel Door

- MKS Proportional Vacuum Control

- Water Ring Pump

- 21 CFR Part 11 Compliant Software

- Validation Documentation

- Factory Acceptance Testing

- Site Acceptance Testing

- IQOQ Workbook

*Standard CIP systems are designed for water use only. Other media may not be compatible and need to be disclosed and/or approved prior to contract.

CONFIGURATION EXAMPLES

| CONFIGURATION | 8 | 12 | 30 | 50 | 60 | 96 | 144 | 250 |

|---|---|---|---|---|---|---|---|---|

| SHELF AREA (sq ft) | 8 | 12 | 30 | 48 | 60 | 96 | 144 | 250 |

| SHELF AREA (sq m) | .74 | 1.1 | 2.78 | 4.44 | 5.57 | 9.29 | 13.3 | 23.22 |

| # OF SHELVES | 4 | 6 | 10 | 5 | 6 | 8 | 12 | 13 |

| SHELF SIZE (inxin) | 12x24 | 12x24 | 18x24 | 30x48 | 30x48 | 36x48 | 36x48 | 48x60 |

| SHELF SIZE (mmXmm) | 300x600 | 300x600 | 450x600 | 600x915 | 600x915 | 915x1219 | 915x1219 | 1219x1500 |

| CONDENSER CAPACITY (LITERS) | 25 | 30 | 75 | 100 | 150 | 200 | 300 | 600 |

| CONDENSER TEMPERATURE | -75C | |||||||

| SHELF TEMPERATURE | -60C to +60C | |||||||

| COOLING | WATER COOLED COMPRESSORS | |||||||

For reference only. Actual configurations may vary based on design for application needs.

Millrock Technology:

Your Freeze Drying Partner

When you purchase a Millrock product, you get more than a freeze dryer. You get a long-term partner delivering industry-changing innovations, high-performing products, and on-call expert support.