EPIC Freeze Dryer

Perfect for Small Scale Production

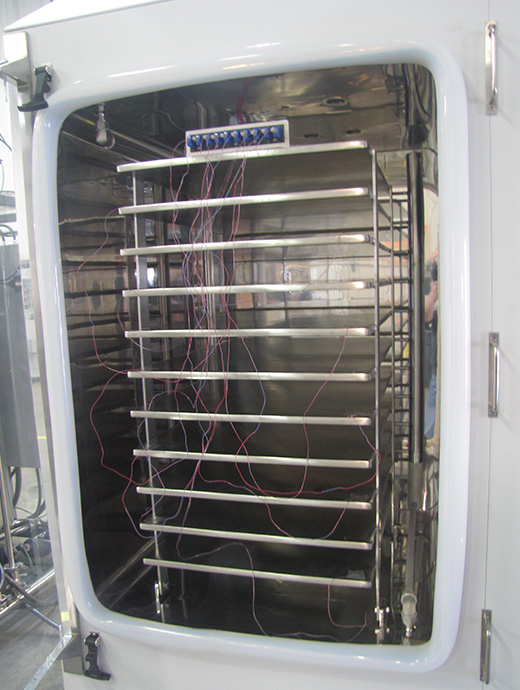

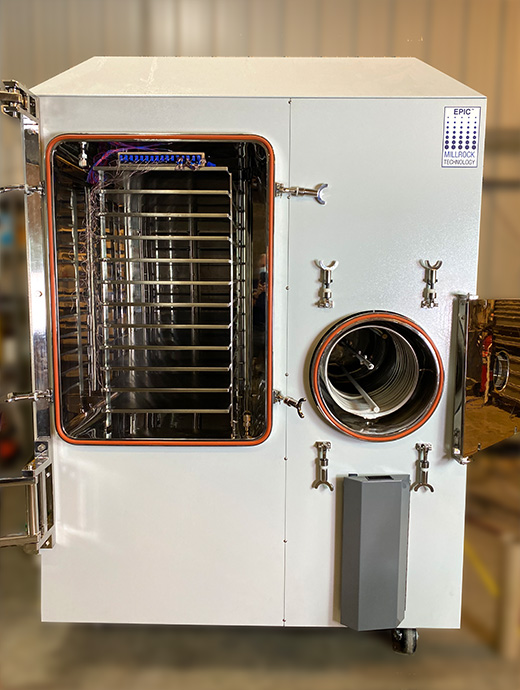

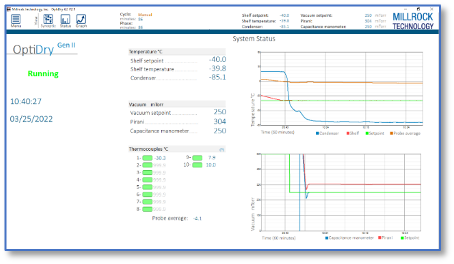

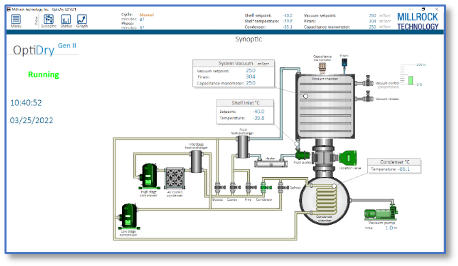

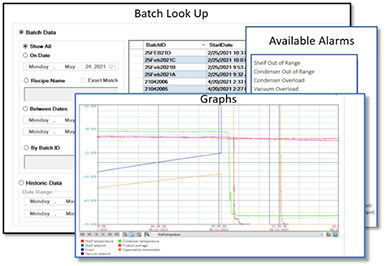

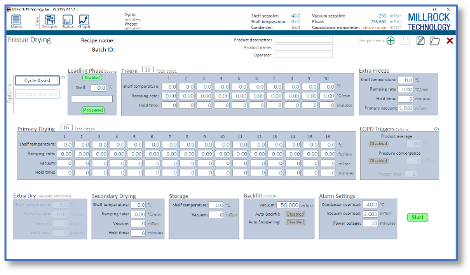

The EPIC Small Production Freeze Dryer offers up to 30 sq. ft (2.787 sq M) of shelf area with a condensing rate of 40 Liters in 24 hours and a capacity of 50 liters. With these specifications the price and performance of the EPIC Small Production Freeze Dryer beats anything in its class. Standard features include PC/PLC controls for data collection, self-testing features (automatic freeze-drying, defrost, and system and leak rate testing. Additionally, remote connection is available to allow for a simple troubleshooting and customer services with customer approval.

In addition to our standard features, advanced system option includes Clean in Place (CIP). This combination provides the ideal platform for simplified and optimized protocol development. Cooling Methods include Water Cooled Mechanical Refrigeration or NitroLyo/LN2 Option.

We have addressed common application issues in our design to ensure that the equipment does not a limit your freeze drying needs. These features include:

- More accurate vacuum sensors

- Superior shelf temperature uniformity

- Reduced shelf temperature transition times

- Increased stoppering pressure

- No rubber hoses

- No vapor flow choke points

About the EPIC Freeze Dryer

Millrock Technology:

Your Freeze Drying Partner

When you purchase a Millrock product, you get more than a freeze dryer. You get a long-term partner delivering industry-changing innovations, high-performing products, and on-call expert support.