STELLAR Freeze Dryer

Versatile Laboratory Freeze Dryer

Looking for a freeze drying workhorse for your lab? We have listened to all of your requests for a hardworking, versatile lyophilizer to be used in applications from proof of concept to small scale production. The STELLAR Laboratory Freeze Dryer provides more performance and capacity than any other unit in its class offering up to 6.25 sq. ft. (0.591 sq M) of shelf area and a condensing rate of 12 Liters in 24 hours.

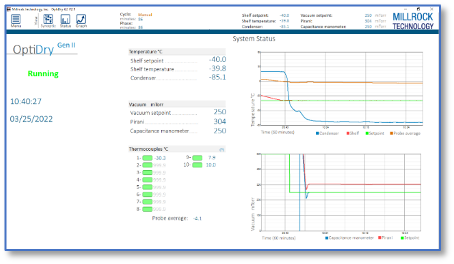

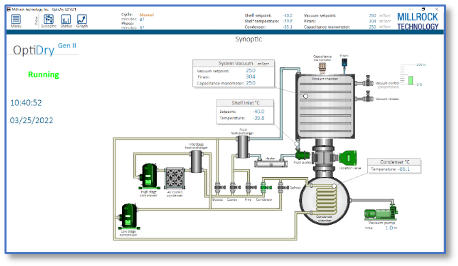

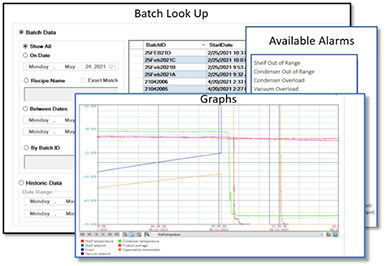

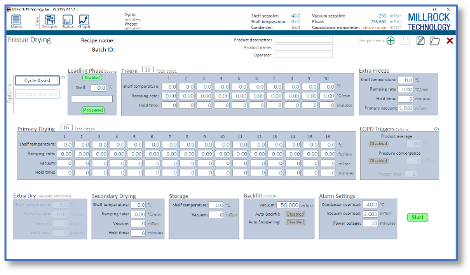

Millrock Technology’s economical STELLAR Laboratory Freeze Dryer combines many of the features of larger systems, such as the Opti-Dry® Gen2 and PLC lyophilization control system, into a small package. It’s ideal for most labs, fitting a wide array of freeze drying applications from investigational laboratory work to diagnostic kits. This tray lyophilizer combines top of the line components and design techniques in addition to options such as: a manifold, capacitance manometer, hydraulic stoppering, and more. Cooling Methods include water or air Cooled Mechanical Refrigeration or NitroLyo/LN2 Option.

SYSTEM PERFORMANCE

- 5 Shelf pull down from +20 to –40C in less than 30 minutes

- Vacuum pull down to 100 mT in less than 20 minutes

- Vacuum leak rate less than 30 mT per hour

- Vacuum level 10 mT in clean dry system (-85C)

About the STELLAR Freeze Dryer

Millrock Technology:

Your Freeze Drying Partner

When you purchase a Millrock product, you get more than a freeze dryer. You get a long-term partner delivering industry-changing innovations, high-performing products, and on-call expert support.