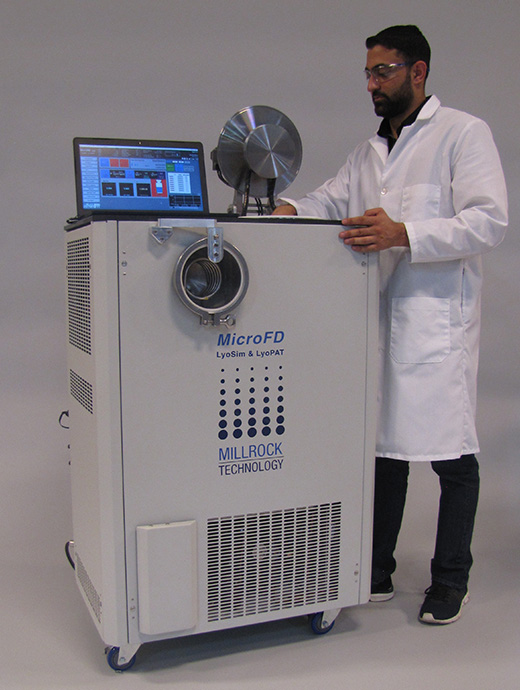

Meet MicroFD

A Revolution in Lyophilization

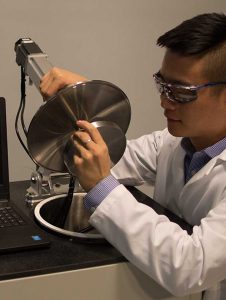

The MicroFD from Millrock Technology changes freeze drying research, development, and cycle transfer forever— a small-scale lyophilizer that delivers more with less:

- Total control over both the freezing and drying phases

- Real-time data for analysis and optimization

- Less of your valuable API, time, and costs

Proven to Develop Transferable Protocols

The MicroFD delivers a R&D and Cycle Development freeze dryer that:

- Takes the guesswork out of protocol development

- Uses less of your valuable product for R&D

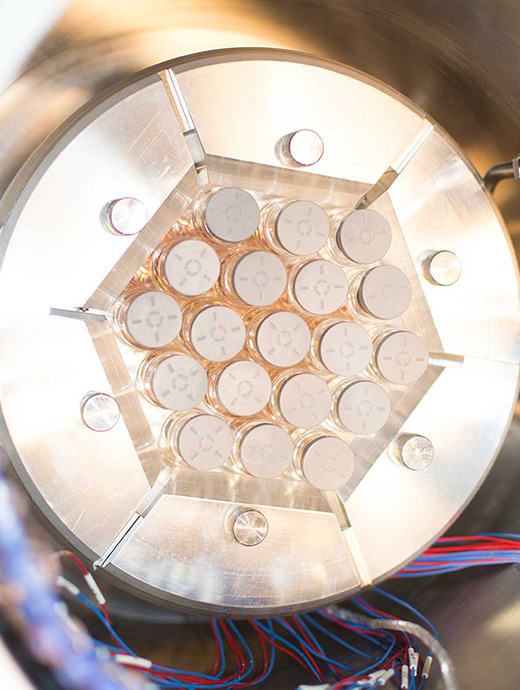

- Enables analysis and optimization with as few as 7 vials

- Determines Kv, Sublimation Rate, Rp and other critical process parameters

About the MicroFD Freeze Dryer

CONTROL SYSTEM

- PC/PLC with ethernet and remote Internet connectivity

- Manual and automatic operating modes

- Graphic and numeric data collection

CONDENSER

- External with Isolation valve

- Exposed coil condenser for maximum efficiency

- Hot gas defrost

- 0.5 L total capacity

- -70C

REFRIGERATION

- Cascade refrigeration system

- CFC-Free, non-proprietary refrigerants

VACUUM

- Pirani and Capacitance Manometer vacuum sensor standard

- Advanced Proportional Vacuum control standard

- Gas backfill standard

- 65 LPM corrosion resistant vacuum pump with easy access

OTHER

- Sanitary style fittings on all sensor and vacuum ports

* Patented and Patent Pending technology.

Note: Specifications subject to change without notice. All specifications based on 20C ambient on 60Hz.

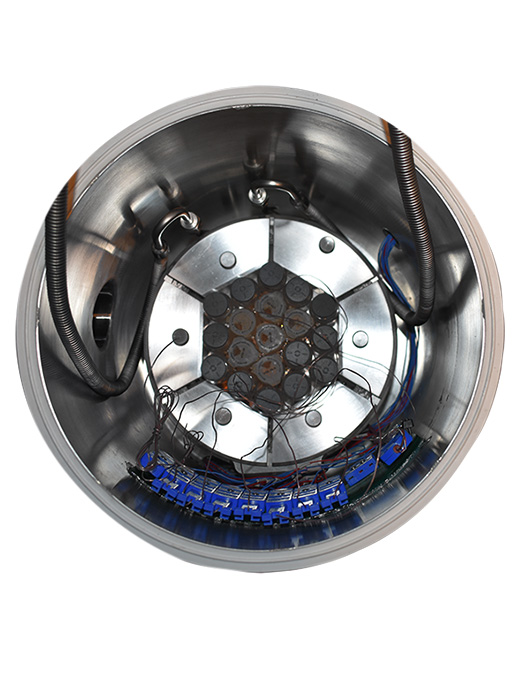

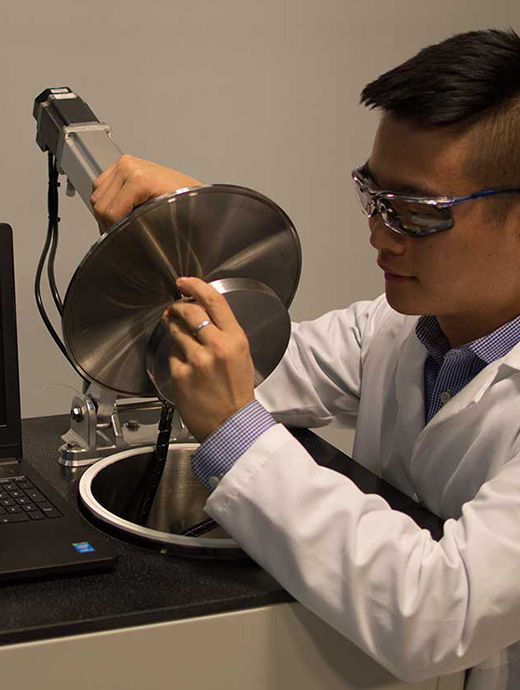

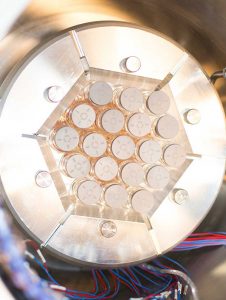

Inside the MicroFD

Millrock Technology’s MicroFD has been refined and improved in partnership with industry experts who are passionate and driven to advance the products, processes, and performance of freeze drying technology. It requires no third-party hardware, and every feature you need is built-in.

LyoPAT® state-of-the-art control capabilities to monitor and control every possible aspect of the freezing and drying processes.

The LyoSIM®ring provides optimal process control via a closely coupled temperature source that can simulate center vials or the edge effect for process analysis. The close coupling of the LyoSIM ring results in far superior results than simply controlling the wall temperature.

AccuFlux® the only technology that provides heat flow monitoring and control— including direct measurement of Kv and mass flow—throughout the entire freezing and primary drying processes.

AutoDry® totally automates primary drying by driving as much heat into the product as possible without exceeding the critical product temperature.

FreezeBooster® controlled nucleation enables the ability to study freezing approaches and its effect on the product and product cycle.

Millrock Reporter provides batch reporting in the format you design.

Features in the MicroFD are patented and patent pending.

See how the MicroFD can help you with protocol development, cycle optimization and cycle transfer. Watch this presentation that introduces the MicroFD & LyoPAT technology

Learn more about developing transferable Freeze Drying protocols using Accuflux and the MicroFD Freeze Dryer

Millrock Technology:

Your Freeze Drying Partner

When you purchase a Millrock product, you get more than a freeze dryer. You get a long-term partner delivering industry-changing innovations, high-performing products, and on-call expert support.

Additional Information

Step 1: Protocol Analysis

Analyze your existing protocol by collecting the critical process parameter data for both the freeze drying and primary drying cycles, including Heat Flow, Product Temperature, Mass Flow, Kv, Rp, and more, determined by the most advanced Process Analytical Technologies. Why use outdated technologies that provide only intermittent monitoring and extensive calculations to predict critical process parameters? With the MicroFD, you get real-time, continuous process measurement and unparalleled control.

Step 2: Cycle Optimization

Save money and time by developing robust products with the shortest freeze drying cycle times. The MicroFD provides you with the tools to optimize both your freezing and primary drying cycles, in order to develop the shortest freeze drying time and critical process parameters for cycle transfer. The MicroFD is the first system of its kind to deliver this level of optimization and data to the freezing cycle.

Step 3: Cycle Transfer

Scale up, scale down the future lies in both directions. With the optimized critical process parameters, you can use the MicroFD for scale-up of new freeze drying protocols, or scale-down analysis and troubleshooting of existing protocols

Whitepaper: "Studies Leading to the Development of the MicroFD”