The Ultimate Tool for Cycle Optimization & Transfer

LyoPAT is the combination of our proprietary AccuFlux® and Auto-Dry™with optional FreezeBooster® technology

LyoPAT combines innovative and powerful control technology into a single integrated control platform that provides research & development and cycle transfer scientists the best tools available on the market today. Included are:

AccuFlux Heat Flux Measurement

- Direct measurement of shelf surface temperature and Kv during the cycle

- Determine the values for critical process parameters to enable transfer between freeze dryers

- Evaluate the effect of different freezing methods, including Controlled Nucleation, on primary drying

- Evaluate the best post-nucleation heat flow to produce the best crystal structure for your application

- Evaluate the effect of different shelf temperatures and vacuum levels on product temperature and mass flow during primary drying

- Evaluate critical process parameters for different freeze dryers

- Evaluate critical process parameters for application changes, such as vial or product fill

- Develop optimized freezing and primary drying cycles

Auto-Dry Cycle Optimization

- Feedback directly from product to controller

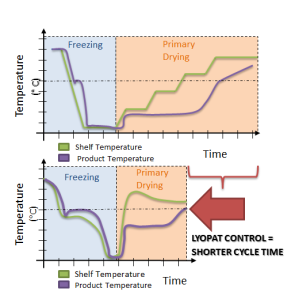

- Maximize heat input while maintaining product below critical melting temperature during primary drying

- Minimize primary drying cycle

Optional FreezeBooster

- Control nucleation of the free ice

- Create a more homogenous ice matrix across the vials in a single batch

- Control batch to batch freezing uniformity

- Study freezing approaches and its effect on the product and the product cycle

LyoSim on the MicroFD®

- Simulate/Emulate the conditions of your larger freeze dryer using as few as 19 vials

- Eliminate edge effect with LyoSim to study center vial conditions

- Cycle transfer by design vs simply run time extension

LyoPAT Benefits

- Non-Invasive

- Non-Interruptive

- Batch Size Independent

- Cycle Optimization

- Post Nucleation Freezing Control

- Measure Kv

- Enhances Quality

- Enables Modeling of Production Systems in the Lab

- Assists in Cycle Transfer

What Does LyoPAT Do?

Millrock Technology has pioneered the use of heat flux sensors to measure and control the heat transfer dynamics of the freeze drying process. This unique technology provides measurement of the Critical Process Parameters in all stages of the freeze drying process, including freezing, primary drying and secondary drying. LyoPAT enables the user to analyze, improve and optimize their freeze drying processes in the lab and easily transfer the protocols to production.

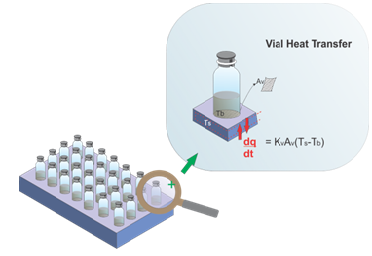

LyoPAT provides direct measurement of vial thermal conductivity (Kv) and heat transfer parameters (heat flux, mass flow, product temperature, cake resistance, etc.).

LyoPAT control software enables existing protocols to be run for analysis or fully optimized by selecting a combination of control parameters.

LyoPAT enables you to continuously monitor your entire freeze drying process

Freezing

- Heat Removed during the freezing process

- % Frozen by Nucleation

- Heat Flow during ice crystallization

- End of Super Cooling (ready for nucleation)

- Controlled Nucleation

- Heat flow control post-nucleation for crystal growth control

- End of Freezing advancement to primary drying based on heat flow stability

Primary Drying

- dQ/dt – Heat Flow

- Kv – Vial Conductivity

- Tp – Product Temperature

- dM/dt – Mass Flow

- % Dry

- End of Primary Drying

- End of Secondary Drying

- Control the process from the product temperature, not the shelf temperature

- And more….

LyoPAT is the only Process Analytical Technology that can determine the critical process parameters in any freeze dryer for your specific application. Protocol transfer is simplified!

If freeze drying process improvement is your goal…

LyoPAT enables you to monitor and control the freezing and drying processes to determine the effect of different protocols on product temperature and primary drying times. This means you can:

-

- Compare your current freezing and drying protocols to new ones.

- Test the effect of controlling crystal growth during freezing.

- Test the effect of controlled nucleation.

- Test the effect of changing shelf temperatures and vacuum levels during primary drying on your product temperature and mass flow rate.

LyoPAT gives the user access to information that did not exist before. This information enhances the development capabilities of your freeze dryer and provides alternatives for scalability as well as quality control.

Millrock’s AccuFlux and Auto-Dry technologies, in conjunction with Millrock’s FreezeBooster Controlled Nucleation Technology, offers a multivariate data acquisition and data analysis platform. Combined, these technologies are called LyoPAT.

Millrock Technology:

Your Freeze Drying Partner

When you purchase a Millrock product, you get more than a freeze dryer. You get a long-term partner delivering industry-changing innovations, high-performing products, and on-call expert support.