Freeze Dryer Restoration and Upgrades

LYO REVIVAL

A second life for your Freeze Dryer/Lyophilizer

Revive your Freeze Dryer!

Don’t have the budget to buy a new Lyo? We will take your existing freeze dryer and make it work/look like new, or even better, make it work like today’s equipment.

Millrock Technology has revived FTS LyoStar as well as Virtis Genesis and Ultra, Usifroid and Hull systems.

Revival ranges from periodic maintenance to complete control system upgrades. Revival includes replacing vacuum lines to eliminate rubber hoses, replace and upgrade the vacuum sensors from thermocouple style to Pirani and repainting the panels to new condition.

Periodic Maintenance includes: replacing the chamber and condenser gaskets, cleaning the air cooled condenser and inside the cabinet, changing the vacuum pump oil and testing the system for proper performance.

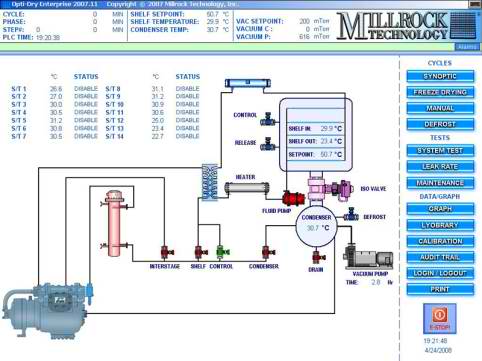

Control System Upgrades replace the proprietary microprocessor or aging PLC with a Ethernet based PC/PLC, providing the latest in process control and data collection. 21 CFR Part 11 controls are also available. Every 5 years technology changes to the point where old control systems are obsolete and not supported. Upgrade to a full PC/PLC control system at the fraction of the cost of a new system.

PC/PLC Control Systems with Advanced HMI

- Touch Screen Control

- Manual and Automatic Modes

- 21 CFR Part 11 Compliant Software Option

- Batch Report Option for all historical runs

Key Benefits

- Fully automated freeze drying control with unlimited recipe

- User Friendly HMI with machine stats and key parameters at a glance

- Ethernet based communication enable monitor and control anywhere with network

- Opti-Dry Pro® option for end of drying detection

- Easy Backup for all system data and configuration settings

- E-mail alarm notifications with dry contact output

- Multilevel numeric of data logging by run and by day, graphic data by day

- Fully customizable to users function specification

- Premier Millrock service and support

- Validateable

Restoration – Complete System Overhauls

After 10 years of operation many of the mechanical components of a freeze dryer have worn out. Get more life out of your system by replacing the major wear parts. Preventative maintenance service is also available.

- Compressors

- Vacuum Pumps

- Fluid Pumps

- Heaters

- Replace Manual Valves with Diaphragm Valves to Automate the Process

- Seals, Fluid and more