Managing Organic Solvents During Lyophilization of mRNA, Peptides, and Proteins

The future of medicine is being written in biol

In many biologic formulations—particularly mRNA vaccines and antibody-drug conjugates (ADCs)—organic solvents are used in upstream processes. Even after solvent scrubbing, trace amounts can remain when the formulation enters the freeze dryer. This introduces serious safety and process control challenges because organic solvents are highly volatile and flammable.

That’s where the right freeze-drying methodology and equipment design become critical. Managing the presence of organic solvents during lyophilization requires specialized engineering to ensure product integrity, equipment protection, and operator safety.

Why Organic Solvents Are a Challenge in Freeze Drying

While water is the most common solvent in traditional lyophilization, some formulations contain organic solvents that present distinct hazards and require specialized handling. These flammable substances can create dangerous conditions inside a freeze dryer if not handled properly.

As Royal Agha, President at Millrock Technology, explains: “Any time you’re dealing with solvents, you have to ask what could cause combustion inside the chamber. You need to remove either the oxygen, the heat source, or the fuel—and that starts with how the system is built.”

Understanding the Fire Triangle—and Engineering Around It

Preventing combustion inside a freeze dryer comes down to disrupting the fire triangle: oxygen, heat, and fuel. To reduce the risk of fire, the freeze dryer decreases oxygen by pulling vacuum and purging with nitrogen. Ignition sources, such as the Pirani gauge, which uses a heated filament to measure pressure, must also be isolated.

- Some of the techniques Millrock uses to manage the risk of organic solvents in lyophilization include:

- Integrating oxygen sensors that verify safe conditions before activating heat-based components.

- Offering systems where Pirani gauges are isolated or eliminated altogether.

- Evaluating all electrical and mechanical components—including thermocouples, capacitance manometers, and motors.

“It goes well beyond just the Pirani,” Agha notes. “Every part of the system may need to be reevaluated depending on the hazard class of the installation environment.”

Solvent Capture: Why Liquid Nitrogen Traps Matter

Solvent Capture: Why Liquid Nitrogen Traps Matter

Organic solvents often have much lower condensing points than water, meaning traditional condensers (−53°C to −85°C) may not capture them effectively. If these vapors bypass the condenser, they can cause vacuum instability, damage equipment, and pose safety risks.

Millrock addresses this by integrating liquid nitrogen traps ensuring volatile solvents are condensed and safely contained.

“Organic solvents are notorious for bypassing traditional condensers,” says Agha. “Liquid nitrogen traps are one of the key components for process safety and vacuum control when working with these materials.”

Why Millrock? Customization Over One-Size-Fits-All

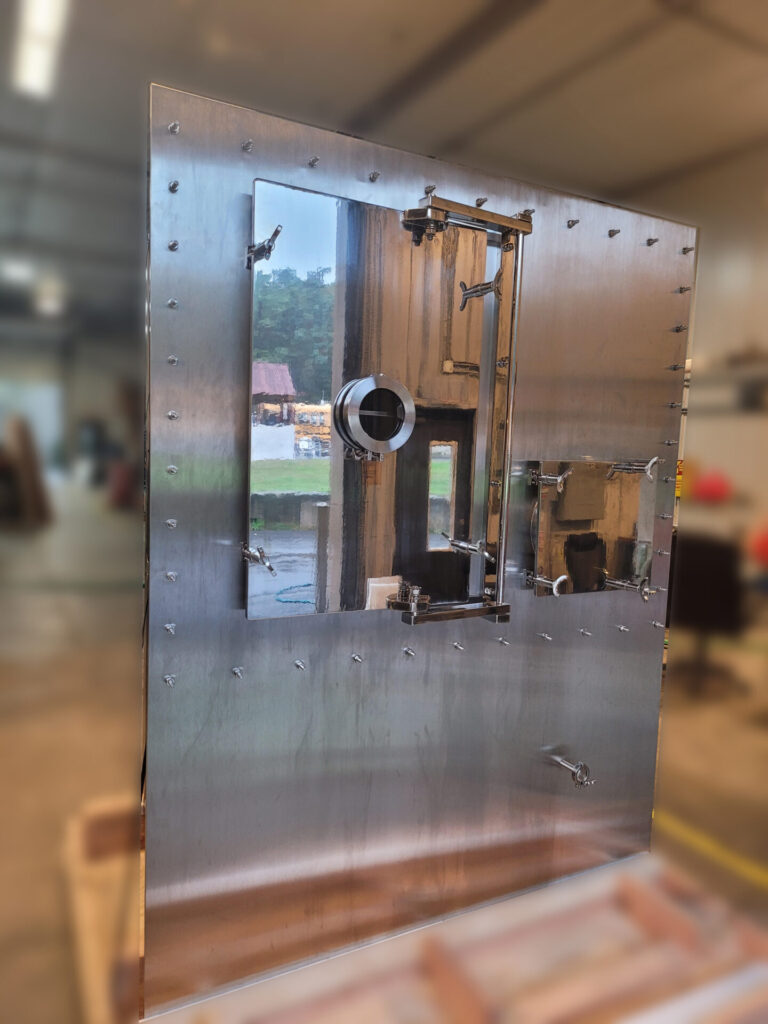

Where others offer off-the-shelf systems, Millrock takes a custom-engineered approach to managing organic solvent hazards during freeze drying. From repositioning components and integrating with isolators to selecting explosion-proof motors and sensors, Millrock builds systems around each customer’s unique needs.

“We don’t just hand over a machine. We work with customers to make sure it’s designed for their exact need,” says Agha. “Tailoring systems to the specific application and environment is what sets us apart.”

This level of precision not only enhances safety but also streamlines the customer’s process, allowing them to scale confidently without reengineering their setup.

Experience Matters in Managing Organic Solvents During Lyophilization

In freeze drying, experience with organic solvent management is more than a differentiator—it’s a safeguard. Attempting to run organic solvent-containing formulations on a standard system without the right safety engineering can lead to delays, inefficiencies, or dangerous incidents.

“Someone trying to do this for the first time will probably hit a few roadblocks,” Agha says. “But we’ve already been there—we know what to avoid and how to do it right.”

Conclusion: Safe, Reliable Lyophilization with Organic Solvents

Conclusion: Safe, Reliable Lyophilization with Organic Solvents

As biologics become more complex, the presence of organic solvents in formulations will remain a reality.

Safely handling these organic solvents during lyophilization is essential to ensuring both product integrity and operator safety.

Millrock Technology is proud to partner with pharmaceutical innovators to design freeze-drying systems that make organic solvent management safe, compliant, and efficient.

Want to Learn More About Lyophilization with Organic Solvents?

Contact our team to explore a system customized for your biologic formulations containing organic solvents.

Solvent Capture: Why Liquid Nitrogen Traps Matter

Solvent Capture: Why Liquid Nitrogen Traps Matter Conclusion: Safe, Reliable Lyophilization with Organic Solvents

Conclusion: Safe, Reliable Lyophilization with Organic Solvents