Production Freeze Dryers

Quanta Production Freeze Dryers for the Life Sciences

Custom designed and manufactured to meet your needs

Whether you need a pharmaceutical quality (c-GMP) freeze dryer or a production freeze dryer for the life sciences at the best price possible, Millrock Technology has a solution to meet your requirements. Each production freeze dryer is custom designed and manufactured to meet your specific application and budgetary needs. As the science and equipment of freeze drying continues to evolve, Millrock's freeze dryers are continuously updated with the latest features and technology. Our production lyophilizers are designed to provide you with optimum performance.

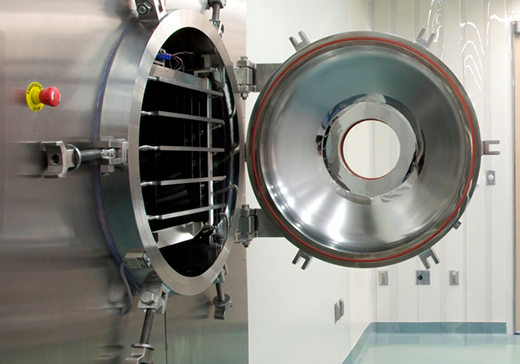

Sterile Production Freeze Dryers for GMP

Many products require freeze drying in a sterile environment, free from cross contamination from batch-to-batch. In production freeze dryers, steam sterilization (aka Steam-in-Place or SIP) is the preferred method. During freeze drying, dryers are under low pressures at low temperatures. The SIP cycle then subjects the freeze dryer to high pressure and high temperature. These extremes in pressure and temperature require special design consideration and construction. Millrock Technology provides steam sterilizable freeze dryers to meet the most rigorous conditions.

Learn more about our QuantaS Sterile Production Freeze Dryers for GMP

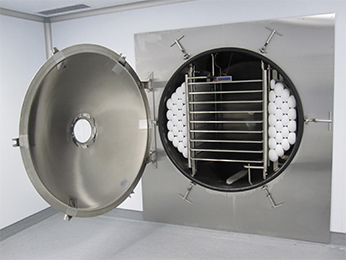

Non-Sterile Production Freeze Dryers

Many products are able to be produced in freeze dryers that are not sterilized nor in a clean room. To accommodate the large range of requirements for these types of freeze dryers, Millrock Technology offers a wide variety of non-sterile production freeze dryer options that will save you money while meeting your production requirements.

Learn more about our Quanta Non-Sterile Production Freeze Dryers for GMP

To find the right freeze dryer for your application,

visit our Compare Our Freeze Dryers page

Millrock Technology:

Your Freeze Drying Partner

When you purchase a Millrock product, you get more than a freeze dryer. You get a long-term partner delivering industry-changing innovations, high-performing products, and on-call expert support.